Tel:86 (755) 6125 6514

Fax:86 (755) 2607 2541

Mobile :+86 188 9836 8729

E-mail:[email protected]

Web:www.yosoint.com

skype:+8618898368729( Daisy)

+8615818641548(Steve)

Add:11B two line Liaokeng Road Shiyan Town Baoan District Shenzhen City 518108 Guangdong provice China

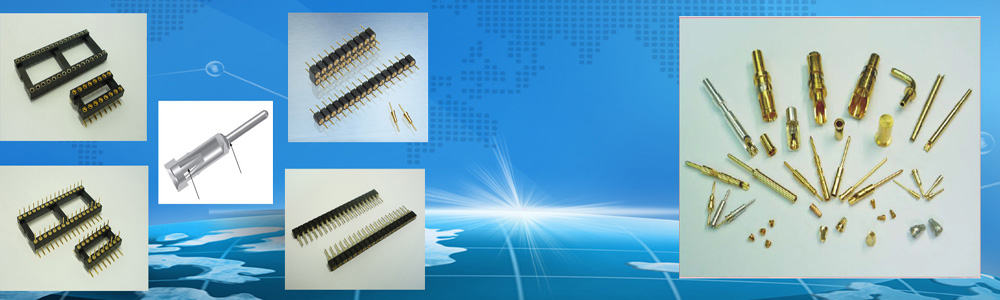

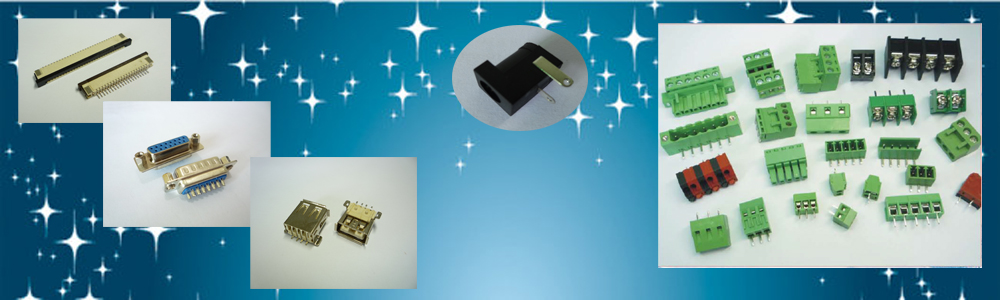

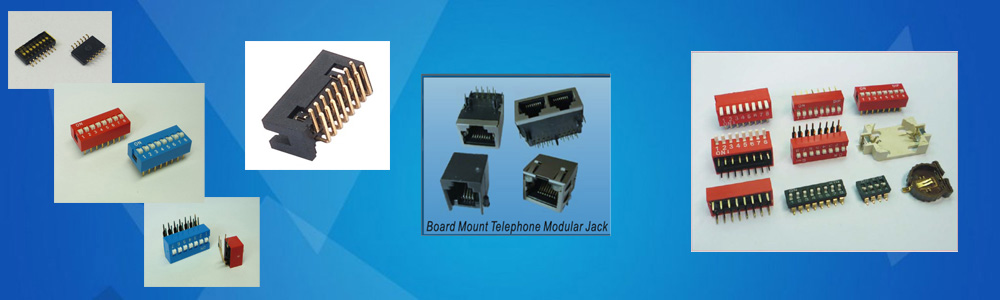

Connector manufacturing

Electronic connector manufacturing from design to finished product, can be divided into two parts, metal and plastic, metal parts in addition to material selection, electroplating and die as main work; Work on the mold is a mold design, open mold, injection molding, and then cooperate with metal component groups made into electronic connector. Electrical even used in electronic products, as the name implies it is play an electronic signal or components connected, it is to belong to a kind of multivariate merger or assembly of products, and cover sheet metal material, surface electroplating, precision processing and plastic molding, and other key technologies. As an electrical signal transmission and connection, in case of problem of electronic connector can lead to partial points in addition to the selection of materials, electroplating and punching die is no all affect the quality of the products, plastic parts, of course, is in the same way the manufacturing including five technology: 1. Stamping die technology. 2. 3. The injection molding technology of electroplating technology. 4. 5. Assembly technology testing technology. Due to the trend of the connector to thin short and SMT, so also need to speed the manufacturing technology for improving the precision requirement, at the same time for makers of precise ideas also change need to produce precision connector, or in the market to the connector at the end of the will be eliminated, due to quality cannot be competitive electronic components and even whole equipment failure. The connector terminals and plastic two major part of the terminal.